Products

Product type

-

Pressure sensors (1)

Pressure sensors are devices that measure the pressure of liquids or gases and convert it into an electrical signal. They are used in a wide range of applications, including the automotive industry, aerospace, medical technology and industrial automation. Pressure sensors are crucial for monitoring and controlling processes, as they provide accurate information about the pressure, which can be used to... -

Digital Panel meters (31)

Digital built-in instruments are electronic devices that are installed in various systems or machines in order to carry out precise measurements and data analyses. They can be used, for example, to monitor temperature, pressure, humidity or other physical variables. These instruments often have digital displays that make it easy to read the values. They can also often be connected to other systems for data transmission or processing. -

Generator controls (11)

Generator controls are systems for monitoring and controlling the operation of electrical generators. They ensure that the generator operates efficiently and safely by monitoring various parameters such as voltage, frequency, load and temperature. These controls can also include automatic start and stop functions to switch the generator on or off as required. They can also activate protection mechanisms to protect the generator from overload... -

HMI Touch Panel (9)

HMI touch panels or human-machine interface touch panels are user interfaces that allow people to interact with machines or industrial processes. These panels usually consist of a touch screen that allows the user to make inputs by touching instead of using physical buttons or switches. HMI touch panels are often used in automation technology, manufacturing, building automation and industrial... -

Power analysers (7)

Power analysers are devices for measuring and analysing electrical power parameters in electrical systems. They record various variables such as voltage, current, power (active power, reactive power and apparent power), power factor and harmonic distortion. These devices are particularly useful for assessing the efficiency of electrical systems, detecting problems such as overload or insufficient power factor and monitoring the quality of electrical energy. Power analysers are often... -

Process controller (18)

What are process controllers and where are they used? Process controllers are systems or devices that are used to monitor and control certain process variables in technical applications. They ensure that a process remains within specified parameters by recognising deviations from a setpoint and initiating appropriate corrective measures. Different types of process controllers 1. proportional-integral-derivative (PID) controllers: These controllers combine three control strategies to... -

Rogovski coils (2)

Rogowski coils are special measuring devices for measuring alternating currents. They consist of a flexible, non-magnetic coil that is wound around a conductor. When an alternating current flows through the conductor, it generates a changing magnetic field that induces a voltage in the Rogowski coil. This induced voltage is proportional to the current flowing through the conductor. A major advantage of Rogowski coils is that... -

Draw-wire encoder (6)

Draw-wire encoders are devices that are used to measure lengths or positions. They usually consist of a rope or cord wound around a pulley. When the rope is pulled or retracted, the movement is converted into an electrical signal. This signal can then be used to determine position or to control machines. Draw-wire encoders are often... -

PLC (5)

Programmable logic controllers, or PLCs for short, are electronic systems that are used to automate machines and processes. They consist of a central control unit that can be programmed to perform various control and regulation tasks. PLCs are often used in industry to monitor and control processes, for example in manufacturing, building technology or process automation. The... -

Rotary encoder (14)

What are rotary encoders and where are they used? Rotary encoders, also known as angle of rotation sensors or torque sensors, are devices that measure the rotational movement or angle of rotation of an object. They convert the mechanical movement into an electrical signal, which can then be used to control or monitor machines and processes. Rotary encoders are used in a variety of applications including: 1. industrial... -

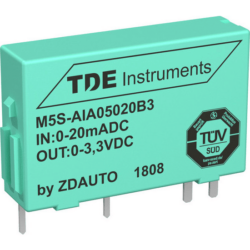

Signal converter ICs (7)

Signal converters ICs (integrated circuits) are specialised electronic components that are used to convert various types of electrical signals. These ICs can, for example, convert analogue signals into digital signals (AD converters) or, conversely, digital signals into analogue signals (DA converters). Signal converters are important for many applications, especially in signal processing, measurement technology and automation technology. They make it possible to convert data from sensors or other analogue... -

Current transformer (11)

Current transformers are electrical devices that are used to measure or transform the current in an electrical system. They convert the high current flowing in a line into a lower, measurable current that is suitable for measuring devices or protective circuits. This is particularly important in high-voltage applications where direct measurements would be dangerous or impractical. Current transformers are often used in power supply,... -

Temperature controller (23)

What are temperature controllers and where are they used? Temperature controllers are devices that monitor and control the temperature of a system to keep it at a desired level. They usually work with temperature sensors that measure the current temperature and a control algorithm that decides whether and how much heating or cooling power needs to be supplied to reach the target temperature. Temperature controllers... -

Temperature sensors (46)

What are temperature sensors and what are they used for? Temperature sensors are sensors that measure the temperature of a medium and convert it into an electrical signal. They are available in different types, including thermocouples and resistance temperature detectors (RTDs). Temperature sensors are used in a variety of applications, including 1. industry: to monitor and control processes in manufacturing, such as in the chemical industry and... -

Linear Potentiometer (26)

What are displacement transducers and where are they used? Displacement transducers, also known as position sensors or displacement sensors, are devices that measure the linear movement of an object and convert it into an electrical signal. They detect the position or displacement of a moving part and are available in various designs, including linear potentiometers, inductive sensors, optical sensors and magnetic sensors. Displacement transducers are used in a...

Stock variants