Rotary encoder

Product type

Output signal

Measurement type

Encoder type

Resolution

-

OPKON MRPF 28 magnetic miniature absolute encoder with solid shaft and 10 V DC analogue output

- from 80,00 € plus VAT.

-

excl. VAT

-

OPKON RPF 28 potentiometric miniature absolute encoder with solid shaft

- 90,00 € plus VAT.

-

excl. VAT

-

OPKON PRI 40SH optical incremental encoder with half hollow shaft

- 99,70 € plus VAT.

-

excl. VAT

-

OPKON PRI 58A incremental encoder with solid shaft for up to 3600 rpm

- 117,80 € plus VAT.

-

excl. VAT

-

OPKON PRI 58SH incremental encoder with half hollow shaft

- 120,83 € plus VAT.

-

excl. VAT

-

OPKON PRI 58H incremental encoder with hollow shaft

- 120,83 € plus VAT.

-

excl. VAT

-

OPKON PRI 50A incremental encoder with solid shaft up to 5000 pulses per revolution

- 108,80 € plus VAT.

-

excl. VAT

-

OPKON PRI 50H incremental encoder with hollow shaft

- 120,83 € plus VAT.

-

excl. VAT

-

OPKON PRI 40A compact incremental encoder with solid shaft up to 1024 pulses per revolution

- 99,70 € plus VAT.

-

excl. VAT

-

OPKON MRI 58A incremental encoder with magnetic scanning

- 99,70 € plus VAT.

-

excl. VAT

-

OPKON MRI 50A magnetic incremental encoder with solid shaft

- 99,70 € plus VAT.

-

excl. VAT

-

OPKON MRI 50SH magnetic incremental encoder with half hollow shaft

- 123,45 € plus VAT.

-

excl. VAT

-

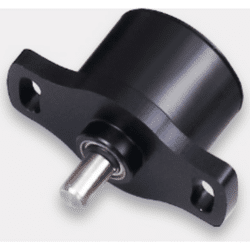

OPKON MRI 40A compact incremental encoder with magnetic sensing

- 90,65 € plus VAT.

-

excl. VAT

-

OPKON MRV 50A magnetic absolute encoder with solid shaft and 5 V DC output signal

- 126,90 € plus VAT.

-

excl. VAT

What are encoders and where are they used?

Rotary encoders, also known as angle of rotation sensors or torque sensors, are devices that measure the rotational movement or angle of rotation of an object. They convert the mechanical movement into an electrical signal, which can then be used to control or monitor machines and processes.

Rotary encoders are used in a wide range of applications, including

1. industrial automation: they help to control motors and machines by providing precise information about position and movement.

2. robotics: Encoders are used in robots to monitor and control the position and angle of the joints.

3. vehicle technology: They are used in vehicle dynamics to measure the position of steering wheels or other moving parts.

4. medical technology: Encoders can be used in medical devices for the precise positioning of instruments.

5. aerospace: Here they are used to monitor control surfaces and other moving components.

Overall, encoders are crucial for precise control and monitoring in many technical areas.

Discover precision with our high-quality encoders!

Are you looking for reliable encoders for your applications? Our encoders offer you maximum accuracy and durability, ideal for industrial automation, robotics and many other areas of application.

Why choose our encoders?

- High precision: Our encoders guarantee exact position measurements, which are crucial for your processes.

- Versatile application: Whether in manufacturing, mechanical engineering or automation technology - our encoders are the perfect solution.

- Robust construction: Designed for use in demanding conditions, our products offer a long service life and reliability.

- Easy integration: Our encoders can be easily integrated into existing systems, saving you time and money.

Optimise your processes!

Increase the efficiency and accuracy of your machines with our encoders. Put your trust in our expertise and let the quality of our products convince you.

Stock variants